Home > About us

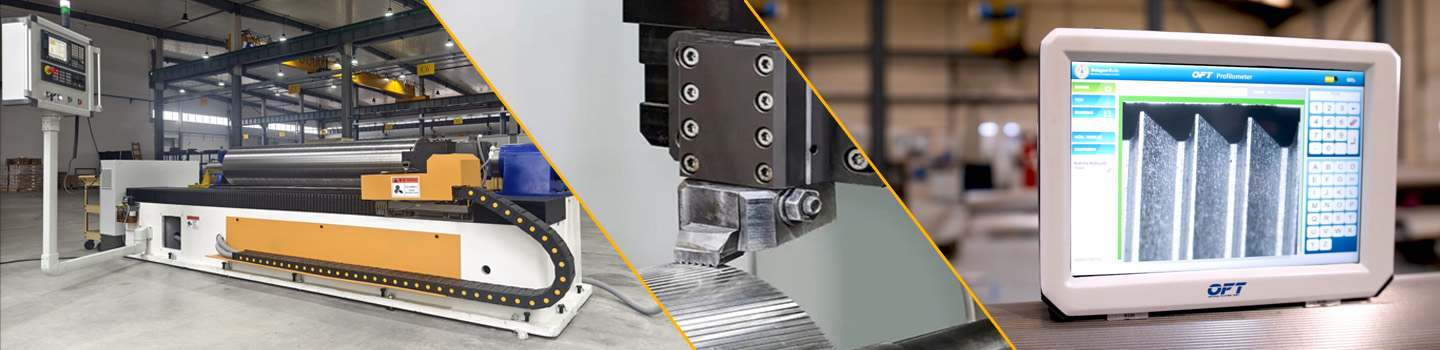

Our facility is equipped with the Fluting/Grooving Machine by Balaguer Rolls, Spain ensuring precision and consistency in roll reconditioning and maintenance.

With this advanced machinery in-house, we offer:

Accurate Fluting & Grooving for all types of milling rolls

Custom Fluting Profiles as per specific milling requirements

Superior Surface Finishing for optimized milling performance

Quick Turnaround with complete control over quality and timelines

Balaguer Rolls is a global leader in roll manufacturing and fluting technology, and this machine allows us to deliver services that meet the highest international standards.

All fluting and grooving operations are carried out on-site under expert supervision, ensuring reliability, accuracy, and efficiency for our clients in the milling industry.

Our facility is equipped with the Fluting/Grooving Machine by Balaguer Rolls, Spain, ensuring precision and consistency in roll reconditioning and maintenance.

It allows us to verify quickly and accurately the state of the flutes in the roll.

With a ±2.2µ accuracy in dimensional measurements and a ±0.01 accuracy in angle measurements can be obtained.

Enables the operator to measure the following elements of a roll profile: pitch, land, dull angle, sharp angle and roll wear percentage.

If any measurement exceeds the tolerances allowed, the system will give the miller a warning.

To use and transport and much more accurate than other existing devices such as magnifying glass or profilometer.

No laptop needed. Just by pressing the button the wear out is calculated

Improved and more precise wear out analysis

Effortless placement of measuring points.

Multiple pictures are taken at once for optimal image resolution

When entering a roll, if it has already been analyzed, all the theoretical data is automatically loaded, which avoids having to enter it again.

When a cylinder number is entered, the history of all measurements made on that roll automatically appears.

Excellent accuracy in all types of flutes.

This system is an essential part of our quality assurance process, helping us deliver consistent and optimised performance in every new & reconditioned roll.